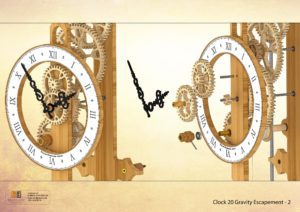

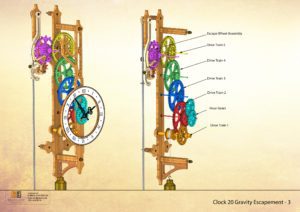

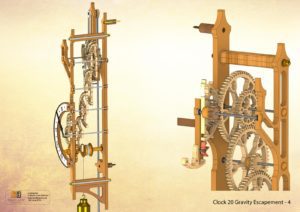

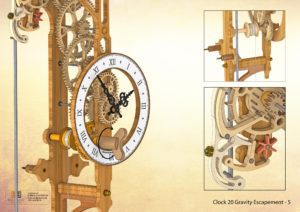

Clock 20 is the first to incorporate the new Woodenclocks Gravity Escapement. The design of this escapement is based on the Arnfield escapement developed by Jim Arnfield in 1987. He devised a method to completely isolate the pendulum from the releasing friction, something that had never been achieved before. The benefit of this is that it reduces the sources of error that can creep into the clock mechanism over time. I have modified the design quite a bit so as to be able to use it in a new wooden clock design. The escapement release parts have all been gathered together at the bottom of the escape wheel to reduce the inaccuracies that can occur over larger distances when using wood. This also has the advantage of reducing the effort needed to release the mechanism so reducing the over all weight needed to drive the clock. The other major change from the Arnfield design to create a 15 legged escapement instead of the 6 legs used in the Arnfield, this slows down the rotation of the escape wheel so reducing the reduction ratio to drive the minute shaft which in turn reduces the driving weight even more. Perhaps the most significant change is the introduction the 6 legged catch that arrests the movement of the escape wheel after each release, this design will always engage the escapement no matter how fast it moves thus removing the requirement for large paddles to slow it down, allowing time for the catch to engage.

I have used miniature ball bearings to support all the shafts to reduce friction and ensure that the spring drive can run efficiently.

The prototype shown in the video runs for just over 12 hours with the dial centre at 1560 mm (61.5 inches) above the floor.The accuracy at the moment is +15 seconds in 12 hours, may be able to get this better, but for the moment I am happy with it.

You can view the Detail drawings of the clock and the renders showing in detail the construction along with the instructions for assembly. The free files are restricted and are not suitable for actually making the clock with but all the drawings and renders along with the DXF and DWG files for using with CNC machining can be purchased from the download page.

I wrote a Blog post recently about the development of the new Gravity escapement design and it can be found here.

DXF, DWG 2D files, and the IGS and STP files that can be used with your CNC machine can be downloaded here for $26. You also get the unrestricted version of the PDF files that can be printed at full size.

Drawings for this clock in PDF format can be downloaded here. These free files are restricted so that you can only view them on screen but not print them. Clicking here will download the PDF file directly to your browser, may take a few moments so please be patient.

A brief illustrated description

of the gravity escapement

can be viewed here.

To view the assembly instructions for the clock, click here, these include illustrated instructions to assemble the clock along with details of materials and equipment needed to construct the clock.

To print only a single item of the drawing to scale using Adobe Acrobat Reader, do the following:

Go to Edit, then click on Take a snapshot, move the cursor to the top left of the item you want to print and hold down the left mouse button whilst you drag a box around the item. The inside of the box turns blue and you can now go to File and then click on Print. This brings up the print dialogue, make sure Selected graphic is selected and that the Page scaling is set to None and the click on OK. As long as your printer is connected you will have printed the item at size. Do this for each item you want to cut out.