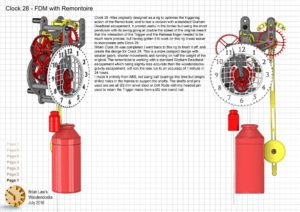

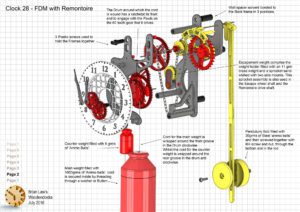

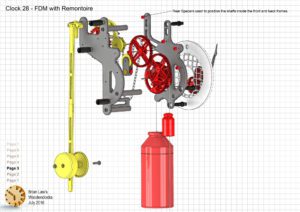

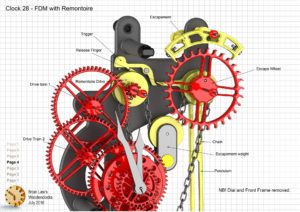

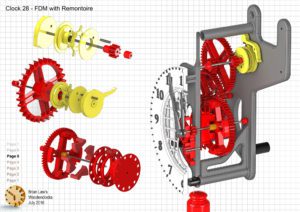

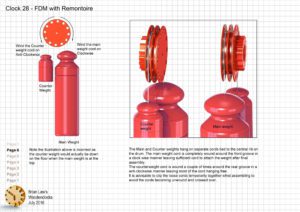

Clock 28 FDM with Remontoire. Clock 28 has been designed to incorporate a Remontoire, it is from the French word ‘remonter’ which means “to wind”. It is a constant force device used in a clock whereby the main source of power periodically lifts a weight by equal amounts and at equal intervals to drive the clock’s escapement. This avoids any irregularities that can be built into the gears forming the clocks drive. The design is based on the Robin Remontoire. It uses a continuous chain drive that has a small weight suspended on the chain between the last gear in the drive chain and an identical gear on the escapement shaft. This weight is the constant driving force for the escapement and will drive it for 30 seconds. At this point, a trigger is lifted to allow the drive train to pull the weight back up again to its start position, at which point the drive train is once again locked. This triggering action is where the design differs from the original Robin design.

I should point out at this point that this clock is quite difficult to build as it involves getting several interacting mechanisms to work in harmony, so if you have little experience building clocks then it’s probably best to try one of the other designs.

This clock was originally designed as a rig to optimise the triggering action of the Remontoire for Clock 26, and to test a version with a standard Graham Deadbeat escapement. It proved useful in doing this so when Clock 26 was completed I came back to the rig to finish it off, and create the design for Clock 28.

This is a more compact design with smaller gears, shorter movements and running on half the weight of the original. The Remontoire is working with a standard Graham Deadbeat escapement which being slightly less accurate than the Woodenclocks gravity escapement, will non the less run to an accuracy of 1 minute in 24 hours. I made it entirely from ABS, not using ball bearings this time but simple drilled holes in the frames to support the shafts. The shafts and pins used are are all Ø2 mm silver steel or Drill Rods with the headed pin used to retain the Trigger made from a Ø2 mm round nail.

● Runs for nearly 13 hours on single cord drop when the centre of the dial is 1530 mm from the floor.

● Main weight 2.5 kg.

● Escapement weight 11 gramme’s.

● Overall Height 190 mm

● Minute hand moves every 30 seconds

● Uses a gravity assisted ratchet to reduce both the noise and the effort needed to wind.

● You can add a simple pulley to get it to run 24 hours but I would advise anchoring the cord to the wall, not the clock frame as you have to double the weight to get it to work with the pulley and 2 kg hanging from the clock is not advised.

STL files, and the IGS files

that can be used with your 3D printer

can be downloaded here for $26.

Drawings for this clock in PDF format can be downloaded here. These free files are restricted so that you can only view them on screen but not print them. Clicking here will download the PDF file directly to your browser, may take a few moments so please be patient.

To view

the assembly instructions for the clock

click here.

Hints and Tips for this clock in PDF format can be downloaded here. Clicking to the left here will download the PDF file directly to your browser, may take a few moments so please be patient.

Download a sample part here,

so you can try the file before deciding to build

the whole of the clock.

To print only a single item of the drawing to scale using Adobe Acrobat Reader, do the following:

Go to Edit, then click on Take a snapshot, move the cursor to the top left of the item you want to print and hold down the left mouse button whilst you drag a box around the item. The inside of the box turns blue and you can now go to File and then click on Print. This brings up the print dialogue, make sure Selected graphic is selected and that the Page scaling is set to None and the click on OK. As long as your printer is connected you will have printed the item at size. Do this for each item you want to cut out.